EMAIS: Megaladata Makes Life Easier for Electronics Manufacturers

For an electronics manufacturing service (EMS), processing multiple bills of materials is part of everyday operation. Each one of these bills includes from tens to hundreds of items. For every item, there are usually dozens of counterparts and alternatives. Comparing the item codes, analyzing technical specs, determining matching items—when all of this is done manually, it becomes a toilsome and resource-consuming routine.

The information about specific spare parts is often scattered across various sources, including:

- Distributor and vendor websites

- Customer CSV and Excel files

- The company's own ERP or database

- PDF documentation

- Emails

This fragmentation makes analyzing the data and choosing the best option draining and prone to errors. The consequences of these human errors can be critical, leading to missed deadlines, complete project cost recalculations, and significant challenges when managing multiple manufacturing streams for different clients simultaneously.

Furthermore, modern EMS often take on the full responsibility for component supply and logistics. Customers expect the final product to be delivered on an exact schedule, with no room for delays. This significantly increases the pressure on the procurement department, which must act swiftly, flexibly, and unerringly to meet these demands.

With the ongoing trend to reduce time to market, procurement is becoming a crucial element of the Electronics Manufacturing Services (EMS) operational and financial processes. The Polish EMS market is experiencing active growth, driven by:

- New projects from Western European customers

- The expansion of the Internet of Things (IoT)

- The growth of the car electronics, defense, and other industries

While order intake is booming, the number of experienced procurement agents on the market is limited. This creates a significant challenge for companies trying to scale their operations and meet increasing demand. Here is some regional research data:

- The average period for hiring a procurement specialist in tech companies: 2 or 3 months.

- The increase in wages of such specialists in 2025: 20–30 % (compared to 2023).

- Additional training required for most newly employed purchasers.

Traditional procurement challenges and risks

Based on numerous observations, a supply manager's routine often involves juggling several sources of information simultaneously:

- A massive Excel table, or even multiple tables

- A web browser with ten or more open tabs for distributors like DigiKey, Mouser, Newark, and TME

- Internal ERP or warehouse database

- The customer's Bill of Materials (BOM)

- Emails from the company's engineers

The manager's goal is to synthesize all this data and obtain a comprehensive picture: what to buy, where, at what price, with which delivery dates, and which purchase option is the best. While these processes are manual, gaining a complete and accurate overview is challenging, and the risk of error is high. Each new project adds to the pressure, overwhelming experienced managers and leaving newcomers feeling lost.

From the business point of view, this creates additional risks:

- Lack of competence in critical points

- Overloading human resources

- Losses due to inefficient decisions by onboarding specialists

For an electronics manufacturing company with tens of concurrent projects, when each customer expects the provider to be "in full control", these issues can be paramount.

Real-life example:

Our client in Poland faced a production delay when their manufacturing partner failed to source the specified STM32 microcontrollers. This triggered a four-day scramble of manual data processing and lengthy email approvals just to find a substitute. The frustrating part? A fully compatible component was in stock and available on the market the whole time, making the delay entirely avoidable.

Such situations occur daily in the EMS sector. However, they are avoidable by using automated tools to analyze options.

Here is the bottom line: In today's EMS sector, a procurement specialist is no longer just an "order placement operator." This role now combines analysis, coordination, and high-pressure decision-making. To effectively manage the workload and mitigate risks, purchasers need modern tools that do more than just help them search for components and spare parts. They need tools that provide smart decision support—automatically analyzing options, highlighting risks, and reducing routine work.

Further on, we will explore how Megaladata integrates a large language model (LLM) to address this particular problem.

EMAIS: Changing the approach to procurement

Typically, the procurement process in EMS starts with the following:

- Analyzing the BOM. The procurement manager typically starts with a CSV or Excel file containing the BOM. The first step is to check which components are already in stock. This process often presents the first set of problems, as the component identifier in the BOM may not exactly match the one in the company's ERP or database. In such cases, the manager must manually compare each component's technical characteristics, which might be incomplete or entirely missing from the BOM. While checking specifications for simple components like resistors and capacitors may be straightforward, it can be much more complex and time-consuming for other component types. Given the vast variety of electronic components, this task is toilsome in itself.

- Compiling the order list. After finding and checking all the necessary information, the procurement manager must prepare the list of components that need to be purchased.

Let's see how both stages change when EMAIS—Megaladata's innovative solution with an integrated LLM—comes into play:

- Import: Megaladata imports data from various sources, including databases, CSV and Excel files, and ERPs.

- Data preparation: The data can then be preprocessed according to your needs, such as being joined, aggregated, or sorted. At this stage, the LLM AI Module is employed to analyze the BOM and determine the key characteristics of each component. With AI assistance, preparing the list of orders becomes significantly faster.

From hours of manual routine to smart automation

Let's see how EMAIS works when applied to real data.

Data import and preprocessing

Step 1. Data import. First, we import data from three different sources: a text file containing the BOM, an Excel file with specifications, and the warehouse database.

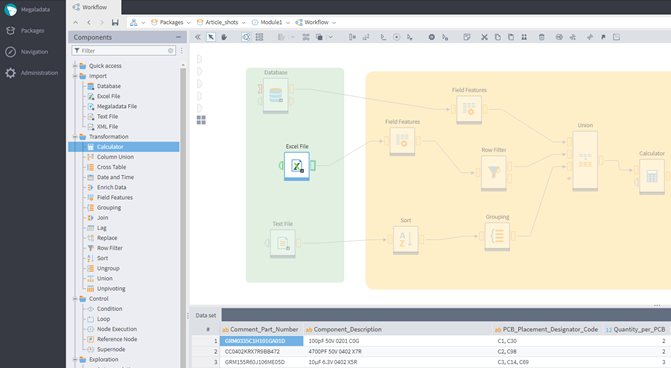

Step 2. Preprocessing. Then, using Megaladata's built-in components, we configure the preprocessing steps—including data grouping, sorting, filtering, aggregation, and union—all through a visual interface that requires no macros or coding.

These two steps are shown in the screenshot:

Import and preprocessing in Megaladata's visual interface

Step 3. Using AI for data analysis and enrichment

Next, we employ the LLM AI Module to analyze the BOM and determine the key characteristics of each component, especially in cases where specifications are missing. This step automates the manual process of looking up missing data, ensuring accuracy and saving time.

Step 4. Analyzing stock balance and creating an order list

After we've parsed and normalized the BOM using our data management tools, and received clear component descriptions and specifications, we need to compare the list with our current stock to compile the order list. While this sounds simple, in practice, this task has its pitfalls. Here's why:

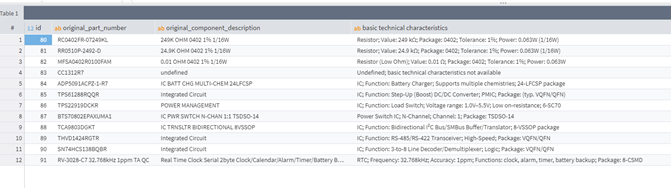

Usually, the result of the previous step is a table of components with the following fields:

- Component description

- Key characteristics: type, value, voltage, frequency, package, etc.

Meanwhile, the data in warehouse databases often "lives its own life". For example:

- A single item can have multiple names: "RES_10K_0402" versus "10kΩ ±1% 0.063W 0402"

- Company names may differ, too: "Murata" vs. "MuRATA Manufacturing Co. Ltd."

- Sometimes, the warehouse database only has internal identifiers, which require previous mapping

In such cases, simple search by name won't work. Let us expand on how EMAIS solves this issue.

After receiving stock balance as an input, the system automatically performs the following steps:

- Matching component characteristics. Even if item names don't match, EMAIS compares key characteristics like values, package, and tolerance. When these properties align, the system identifies a match, marking the item as "in stock."

- Search for counterparts. If an exact match is unavailable, the system searches for other fully compatible components in stock that can serve as direct replacements.

- Assessment of available quantities. The system calculates whether the current stock quantity is sufficient to fulfill the order and determines if an additional purchase is required.

As a result, the system outputs a cleaned list of items to order—the components that are either out of stock or not enough (e.g., you need 1000 units, and there are only 300 in stock):

Output table: list of components to purchase

As the workflow is clear and visual, it is easy to explain to any other department, e.g., Manufacturing or Logistics, why this or that component is included in the list.

The advantages of automation

- Saved time: The task that used to take half a day—working with Excel and checking everything manually—now takes minutes. No more manual pivoting of tables, copying and pasting, decrypting name variations, and searching through every provider's website.

- Reduced errors: The human element doesn't affect the results as it used to, especially for large BOMs, where it's easy to miss some detail.

- Transparency: It's easier for decision-makers to understand why something needs to be purchased and what amounts will be spent.

Step 5. Automated collection of supply offers: Where, when, and how much

When we have a clear idea of what we need to buy, the next stage is researching the actual prices and offers. We need to find out how many items each provider has, how soon they can deliver, and how much it will cost. The process is similar to trading on the stock market, but instead of brokers and phones, it uses a RESTful API and Megaladata with integrated AI..

Traditional manual data collection would look like this:

- Enter the provider's website

- Search through their catalogs by pasting part numbers

- Copy and paste listed prices

- Compare the information on different tabs

- Repeat for each component

Knowing that a BOM most likely contains not five but 150 components, and there may be several BOMs to process, this can turn into a real pain. EMAIS makes things easier!

Through APIs, the system's ready-made library integrates with all the main electronic parts providers: DigiKey, Mouser, Farnell, TME, etc. Then, the following operations occur:

- We input the list of necessary components.

- The system automatically calls the providers through APIs.

- The workflow outputs structured data:

- current cost (considering the necessary amount)

- availability in stock

- the minimal order quantity (MOQ)

- delivery dates

- limitations (e.g., only for industrial use)

This data forms a clear and comprehensive table that facilitates decision-making.

Step 6. Automated substitute search

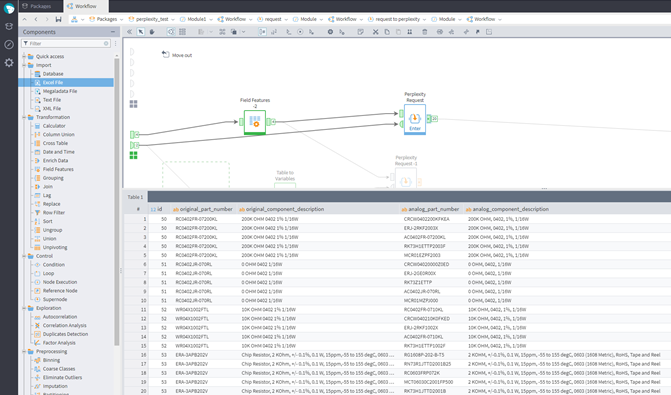

In case a component cannot be found or costs too much, EMAIS searches for alternatives using the LLM AI Module. The AI agent not only suggests similar products, but also:

- checks the compatibility by key characteristics (material, electrical specs, temperature, etc.)

- gives confidence: the counterpart can replace the original part and will work!

- most importantly, automatically requests the counterpart's price and availability data from the providers. As a result, you not only see the option, but can purchase the counterpart right away of it's cheaper or takes less to deliver.

The output table provides all the data and numbers for the whole list of components on a single page. This information is enough for the purchaser to make the final decision:

Output table including counterparts

Advantages:

- Much less routine work. No more copying and pasting part numbers on many websites, manual availability checks, and stock comparison.

- Seeing the options. You can take balanced decisions: what is cheaper, what is faster, and what is more secure.

- Transparency and repeatability. If John purchases today, and Jane tomorrow, the result will be the same.

- Less time to react. The faster you collect the data, the faster you order, the less production downtime you have.

Step 7. Creating the optimized procurement plan

The next—and the most "technical"—stage of the process is generating the procurement plan. Based on the output table you have, the task is now to balance cost against other criteria (e.g., delivery dates) and work out an optimal plan, taking into account all the limitations, risks, and goals. Let's first describe it in detail and then illustrate it with a mathematical model.

A procurement plan is a document (typically a table) indicating the following:

- The components to purchase and the necessary quantities

- The suppliers to purchase every component from

- Their sale conditions: prices, volumes, dates, MOQ, logistics, etc.

The purpose of this document is to complete the BOM with maximum efficiency, that is, quickly, securely, and with minimal possible expenses.

Input data

At this stage, the input data we have are the following:

- The number of components required (according to the BOM): Qi, where i is the component index

- A list of providers' offers: with prices and MOQ

- Available counterparts, in case some components are hard to find, or their sales conditions are not preferable

- Stock balance that can be used to partly complete the BOM

- The customer's or manufacturing limitations: deadlines, budget, delivery map, etc.

Important limitations

- Minimal Order Quantity (MOQ): You can't order less than the minimum amount required by the provider.

- Lead time: Some items may be needed on a tighter schedule than the provider can accomodate.

- Financial limitations: You can't spend more than the allocated budget.

- Preferences about the distributor: The company or the end customer may prefer some providers over others.

- No counterparts in one order: Items that can replace each other shouldn't be added to the same order. For some components, like integrated circuits or power elements, this is particularly important.

- Warehouse and logistics limitations: The available supply and the number of orders may be restricted.

Goal function

What is the specific goal of our optimization? They can be different, but in practice, the following goal functions are often used:

-

Minimal total purchase cost: This is the most common and obvious metric.

-

Minimal delivery time: Used when the deadlines are tight and crucial.

-

Balancing costs and delivery time: It's possible to combine budget limitations and time preferences in one goal function when both are critical.

Using EMAIS

After you load all the input data, the system performs the following steps:

- Considering the conditions: The system filters out offers that don't meet specified limitations, such as a delivery time that's too long, no delivery available, or a MOQ that's too large.

- Activating the optimization module. The system employs an optimization module, that uses a simple greedy algorithm for shorter BOMs and linear/integer programming for more complex tasks.

- Delivering results: The system outputs the results, which include:

- a procurement table that details what to buy, where to buy it, the quantity, and the cost

- the total cost and time assessment for completing the order

- alternative scenarios, such as a slightly more expensive option that's three days faster

Example:

A project requires purchasing 2,500 DC-to-DC converters.

- Mouser offers 1,000 units at $0.95 per unit

- TME has 2,000 units at $1.10 per unit but offers faster delivery.

The system suggests the following options:

- Purchase 1,500 units from TME to meet project deadlines.

- Purchase the remaining 1,000 units from Mouser. These will arrive later but will be slightly cheaper.

- Alternatively, order the entire quantity from a single provider to simplify logistics.

You receive all these options with detailed calculations automatically, without tap-dancing around Excel and other resource-consuming routines.

Step 8. Order finalization and transfer

Now that we have an optimal procurement plan, where costs and delivery dates are carefully balanced and all additional limitations have been considered—it's time to finalize the orders and transfer them to the relevant integrated systems.

Traditionally, the purchaser at this stage performs the following manual steps:

- Copies the plan into an Excel file

- Manually creates a purchase order

- Sends emails to providers or enters data into their portals

- Double-checks all supply conditions, such as dates, costs, and logistics

- Copies all this data into an ERP or warehouse software. While system integration is ideal, it is not always available, requiring additional manual data entry.

This manual, multi-step process is time-consuming and prone to human error, highlighting the inefficiencies of traditional procurement workflows. The automated EMAIS solution makes it all easier and faster. Here's how:

- Order finalization: Based on your procurement plan, the system automatically groups the items by supplier, generating a separate purchase order for each vendor.

- Order export and transfer: The solution completes the procurement process with one of the following operations:

- Direct ERP integration: The system loads the data directly into your ERP, eliminating manual data entry and copying. If your company's ERP has an API, the order is generated automatically without any human intervention. All operations are logged for easy review.

- File export: The data is exported in the required format (e.g., a CSV file) for transfer to the necessary system. The file includes essential details such as item labels, prices, and provider links.

- Automated API orders: The solution can automatically send orders directly through supplier APIs. For example, popular platforms like DigiKey and Mouser support direct ordering via their APIs.

- Component list generation: A final component list with all the details is generated, which the purchaser can then edit or forward as needed.

Overall benefits of using EMAIS

- Eliminate dependence on individual expertise. The procurement process no longer relies on a specific person's experience or their skills with ERP systems and Excel.

- Create a transparent and predictable process. The entire procurement workflow becomes transparent, reproducible, and controllable. This ensures consistency and makes it easy to track every step.

- Enable fast, data-driven decisions. Managers and decision-makers can quickly identify bottlenecks and risks to react proactively and avoid issues.

- Reduce errors and delays. Minimizing manual operations leads to fewer errors and faster turnaround times.

- Increase client satisfaction. Faster production starts, a direct result of improved efficiency, lead to increased client satisfaction.

Procurement turns from a bottleneck into a strategic advantage!

Summary: Results and how we achieve them

Manual procurement in EMS is inefficient and costly. Every step—from editing BOMs and comparing lists to sourcing components and emailing suppliers—presents opportunities for errors, delays, and financial loss. EMAIS goes beyond simple speed. Our solution transforms the entire procurement process, replacing manual tasks with a streamlined, intelligent workflow. The results speak for themselves and are detailed in the table below:

| Result | How we achieve it |

|---|---|

| Reduce purchase preparation time 3–5x | By automating BOM analysis, identifying counterparts, and aggregating real-time price and availability data |

| Save 5–15% on the procurement budget | By optimizing procurement plans through a better balance of cost and delivery time, and by analytical comparison of suppliers and logistics |

| Reduce dependence on individual specialists | By systematically processing information, preventing critical knowledge from being held by a single person |

| Reduce errors and recalculations | By eliminating manual data entry and automatically verifying all data |

| Improve flexibility for force majeure or shortages | By enabling fast recalculation and identifying alternative providers or part counterparts |

| Increase managerial transparancy | By consolidating all metrics, forecasts, and risks into a single, comprehensive dashboard |

Implementing EMAIS

If you're considering a new procurement approach, you don't have to change everything at once. We recommend following these steps one by one to make the transition smooth:

- Analyze your BOMs. Start by uploading your BOMs to our platform. Review the processing, including how it identifies characteristics, finds counterparts, and matches components with suppliers.

- Connect supplier APIs. Integrate with your suppliers' APIs to automatically collect real-time data on prices, lead times, and stock availability.

- Configure analytics. See how the platform generates detailed reports and procurement plans and compares the options. This provides valuable insights, even in a semi-automatic mode.

- Esecute a test purchase. Try the complete new workflow, from uploading the BOM to exporting the final purchase order.

- Integrate your data. Once you understand the advanatages of the platform, it's time to integrate your ERP or database. Unify all your data—orders, shipments, components, and stock levels—into a single automated system.

In conclusion

Implementing digital solutions like EMAIS isn't about replacing people with AI. Instead, it's about equipping your specialists with powerful tools to eliminate tedious, manual work like data entry. This frees up their time and resources, allowing them to focus on high-value, strategic decision-making. If you are an electronics manufacturer or a purchasing manager in a EMS company, now is the ideal time to embrace this new approach. In today's market, competition is no longer just about price—it's a race for efficiency, where automation consistently outperforms manual processes.

See also